PP Filament Spunbond Needle Punched Nonwoven Geotextile

PP filament spunbond needle punched nonwoven geotextile uses polypropylene as raw materials, is processed by spinning, airflow laying, needle punching and other processes

Message

Details

PP filament spunbond needle punched nonwoven geotextile uses polypropylene as raw materials, is processed by spinning, airflow laying, needle punching and other processes

♦Features

Polypropylene filament spunbond needle-punched geotextile has the advantages of high strength, strong puncture resistance, corrosion resistance, anti-microorganism, aging resistance, high temperature resistance, superior water permeability, filtration, soil retention and so on. Compared with polyester filament geotextile, its strength is higher, tear resistance and puncture resistance is stronger, especially acid and alkali resistance, can be in long-term contact with cement, fly ash, lime and other alkaline materials, can maintain stable performance in alkaline environment, no hydrolysis.

♦ Application

It is mainly used for high-speed rail ballastless track isolation layer, tunnel impermeable gasket layer, airport runway isolation layer, highway anti-cracking substrate, water conservancy project revetment bottom, landfill, emergency engineering foundation treatment, ecological slope protection and other engineering fields.

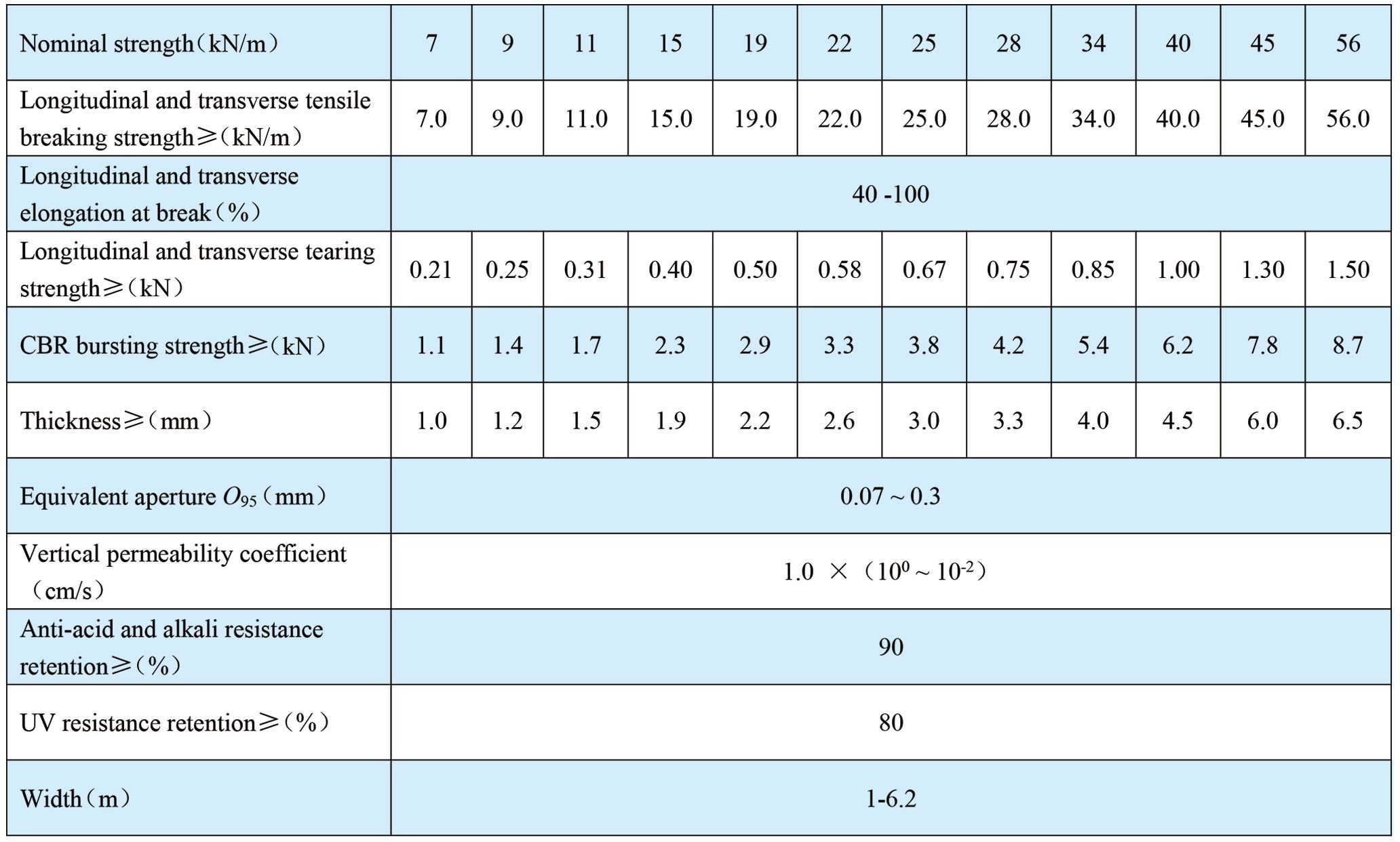

♦ PP Filament Spunbond Needle Punched Nonwoven Geotextile Product Properties

previous page

Uniaxial geogrid, made of high molecular polymer, is extruded into sheet and then punched into regular mesh pattern,and finally stretched in the longitudinal direction.

PP biaxial geogrid is manufactured from PP, it is produced through the process of extruding, punching, heating, longitudinal and transverse stretching.

Fiberglass geogrid is knitted by glass fiber filaments and coated with bitumen to provide a good bond with the asphalt layers, can strengthen the asphalt layer, extend the service life of pavement layers and decrease the occurrence rate of reflective cracking under cyclic traffic load.

Polyester geogrid is made of high strength polyester industrial yarnjt is warp knitted and coated with PVC.lt can be applied to soft soil foundation treatment and reinforcement of subgrade,dam and other projects,so as to improve project quality and reduce project cost.

Multiaxial Geogrid is one kind of plastic geogrid with a stable network structure formed by extruding, punching, and four-direction stretching.

PP Mining geogrid is made of modified polypropylene and other high molecular polymers by extrusion and stretching.